SMOKING SYSTEMS

Thanks to our in-depth cooperation with users, suppliers and liquid smoke producers, LEFA has created the possibility of smoking with so-called combined systems, which pave the way for a new level of smoking with regard to taste and appearance of our products. Thanks to dedicated further technical development, smoking systems can be combined with friction and liquid smoke or smoulder and liquid smoke. Here, you can learn more about the different smoking technologies.

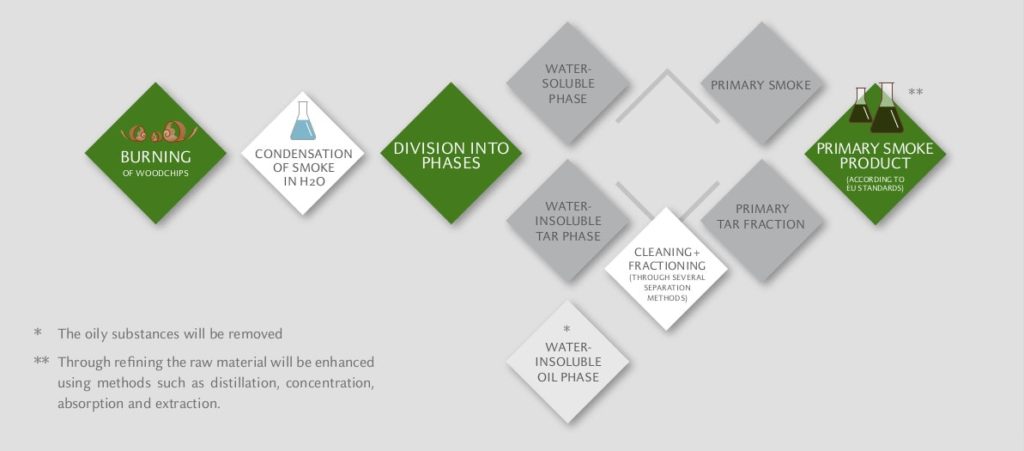

LIQUID SMOKE

Functional description

Easy on the product, free of toxins and environmentally-sound: The LEFA liquid smoke method (European patent No. 0664670)

The liquid smoke method is especially easy on the product, free of toxins and environmentally-sound. A small amount of liquid smoke acquired from untreated woods (beech, maple, alder etc.) is sprayed directly into the fan via the single-component of the fan system. A steam and gas phase forms, which produces invisible smoke that is nonetheless comparable with conventional smoke. The liquid smoke is injected at a pressure of 3 to 4 bar. This process is conducted in intervals. Substances that are hazardous to health, such as tars, are filtered out with this smoking technology.

Benefits

- affordable investment, most-modern technology and uniform quality

- low consumption of liquid smoke – only small quantities of liquid smoke are injected

- no increase in volume when the valves are closed

- environmentally-friendly, clean, no risk of fire

- uniform quality characterised by different smoke flavours, uniform smoke dosing, optimal circulation control and fully automatic operation

- low energy and operating costs

- no highly-toxic tar removers, carcinogenic tars and emissions by the smoke generators

Technical diagram

SMOULDER SMOKE

Functional description

During the smoking phase, a smoke mixture consisting of smoke and conveyor air is produced in the smoke generator. The smouldering process is automatically initiated by a heating rod. The smoking material smoulders within a temperature range of approximately 400–600 °C. The smoke mixture is fed to the processing chamber via a smoke duct.

The burning plate is supplied with the smoking material (sawdust or fine woodchips, grain size 0.7 mm–2.5 mm) in intervals. An agitator with a motorised or pneumatic drive supplies the smoking material via the dosing tube from the storage container. The height adjustment of the dosing tube makes it possible to optimise the supply of smoking material thereby producing the desired smoke density.

Ash from the consumed smoking material falls through the grate of the split cover into the ash box. The electric heating rod for igniting the sawdust is mounted at a short distance outside of the burning plate. The smoulder smoke generator is operated as a half-open circulation unit (closed system, without addition of fresh air).

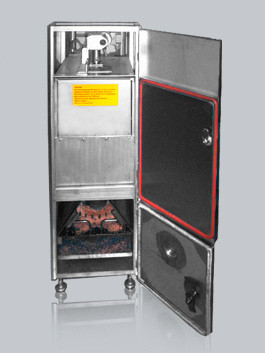

Examples

- Smoulder smoke generators

Technical diagram

FRICTION SMOKE

Functional description

The friction smoke generator

The smoke generator produces aromatic smoke by pressing a wooden stick (dimensions 8 x 8 x 70/100 mm) onto a fast rotating, diagonally-toothed friction wheel. The wooden stick is pressed pneumatically by means of a wood clamp. The resulting pressure (friction pressure) is adjustable.

The friction process is discontinuous, that is, each friction interval is followed by a pause, which can also be adjusted and can also be used to regulate the smoke intensity. The working time for a friction interval (friction time) averages 30–40 seconds.

The pause amounts to approximately 40–60 seconds with hot smoking and approximately 2-4 minutes with cold smoking. Noise insulation to prevent impact sound is installed between the internal and external casing.

Examples

- Friction smoke generators